Soapmaking with Melinda Coss

Monday, January 11, 2016New year, new skill! Soapmaking: tick.

I've been making melt-and-pour soap for a few years, but it was high time to find out how to do it properly ala cold process. And so, I enrolled for Melinda Coss's Cold Process Soap Making Course. She's a pretty well-established authority in craft circles (she actually wrote the book on some of my favourite crafts unrelated to soap) so I figured it'd be a safe bet to choose this one.

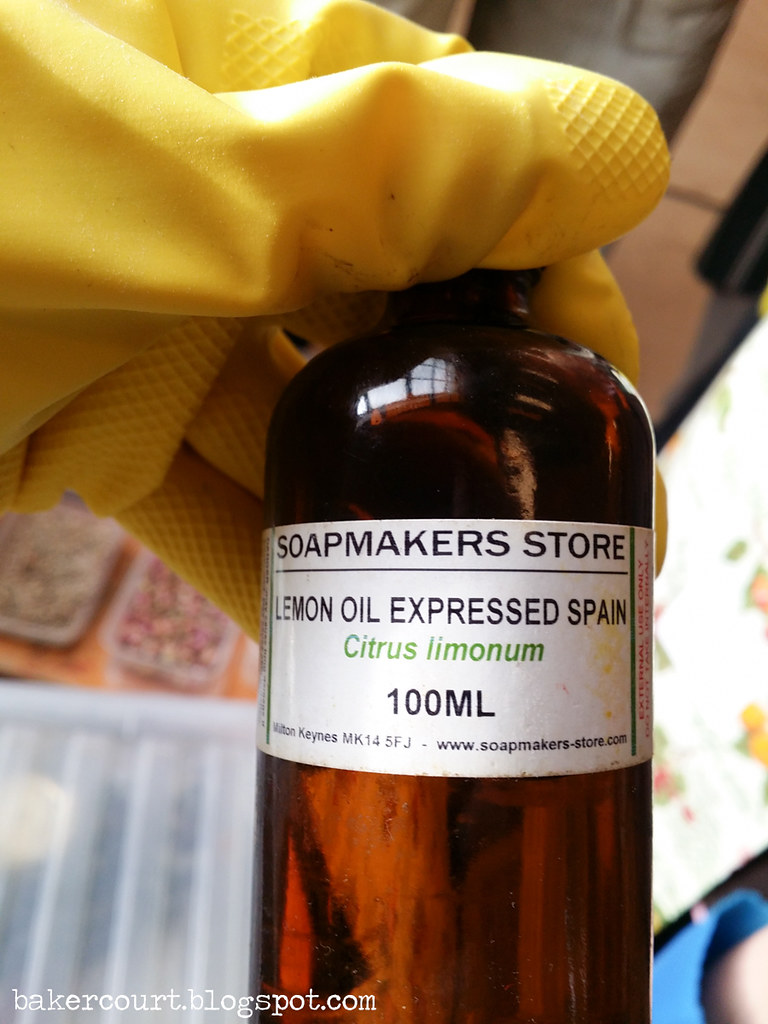

After a morning health-and-safety briefing and introduction, we were split into rubber-gloved groups and set to work on the chemistry bits. We had to pay lots of careful attention to the potentially-explosive sodium hydroxide mixing, so no photos for that phase. Ah well. Measure, melt, mix, stir, blend, stir, blend, stir, flavour, pour, repeat. Make sure you wear your oh-so-trendy goggles and soapmaking accessories.

Rubber gloves are a great look, no?

There were loads of scent, colour and botanical combinations to explore. Poppy seeds, olive pips, roses, nettle, orange peel, clays, more. You *could* put just about anything in soaps - it's all a matter of experimentation.

In the morning we made a goats' milk soap, and in the afternoon we made a basic vegetable fats soap with beeswax which we coloured with various oxides and clays, and decorated with almost everything on the table you see here. Our group had varied opinions and tastes about what we thought soap should be (and not be), but on the whole it was a really enlightening experience - and thoroughly enjoyable. I'm completely inspired to mix up a few batches of soap soon!

This is the basic goats' milk soap which really does look like cupcake batter in those cases. It was suggested that if we used cupcake cases in the future, that we make sure we label any gifts / market supplies / etc. as "not safe to eat". Ha. The cupcake cases enabled us to take some soap home at the end of the day, rather than waiting a few days for a soap loaf to go hard enough to cut.

Some groups were more experimental than others, and the colour combinations were adventurous. Calendula with a purple-tinged oxide. As you do.

There were loads of goodies to buy for soapmaking at home, very tempting. Shopping bags were filled up quickly during class breaks.

There wasn't an awful lot of one-to-one with Melinda; we worked with our individual group tutors so that we all had a chance to get hands-on with the soapmaking process. She did make the rounds to provide feedback and comments, and she also gave a Q&A troubleshooting session after the course which was quite enlightening. I was surprised by the Queen of Crafts - sitting all in black, smoking a vapourised e-cigarette while making jokes about pig fat and pink trousers. Quite contrary to expectations.

All in all, a thoroughly enjoyable day spent measuring, mixing and melting. I feel completely ready to break out the chemicals and make up a few batches of experimental soap, where previously I was intimidated by the lye and potential risks. I can't wait to try out slightly more unusual soap ingredients - processed cucumber! liquid coffee! beer! - and see how they all turn out.

I'd definitely recommend the class to anyone interested in cold process soap making. You get to try out a few combinations, get a clear understanding of the basic process, and you take away plenty of samples to test out when they're ready to use in six weeks' time. There's also ample opportunity for Q&A throughout the whole course and everyone is very approachable.

Watch this space - I'm looking forward to seeing how the experimental class recipes turned out in six weeks' time when they're safe to use. Exciting.

3 comments